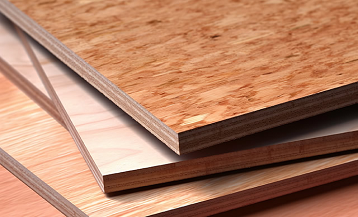

Recently, exciting news has emerged in the industry. we has successfully developed an innovative production process for wood laminated PVC boards. This process not only significantly improves production efficiency but also greatly enhances the environmental performance of the products, promising to reshape the market landscape of wood laminated PVC boards.

As a material widely used in fields such as architectural decoration and furniture manufacturing, traditional production processes for wood laminated PVC boards have long - standing problems, including long production cycles, high energy consumption, and difficulty in meeting environmental protection standards. The new process introduced by we has undergone a comprehensive optimization from raw material selection to the production process.

In terms of raw materials, the company has chosen sustainably sourced wood and environmentally friendly PVC materials. Through advanced pre - treatment technology, the surface of the wood becomes smoother, laying a good foundation for the subsequent lamination process. During the lamination process, new adhesives and heating and pressurizing technologies are employed, enabling the PVC layer to bond quickly and firmly with the wood, greatly shortening the production cycle. Meanwhile, the new process reduces the use of chemicals, resulting in a formaldehyde emission level far below the national standard, which better meets the modern consumers' demand for environmentally friendly products.

Industry experts say that this process innovation by we will bring new development opportunities to the wood laminated PVC board industry, promoting the entire industry towards a more green and efficient direction. With the continuous improvement of environmental awareness, products produced by this new process are expected to gain wider recognition in the market.

Innovation in Production Process of Wood Laminated PVC Boards: Green and Efficient, Leading a New Tr

From:

United Tech Industrial Group Co., Ltd.,

Date:05-24,2025

Hits:421

Belong to:NEWS